A good friend and fellow bamboo rod builder (Skip Hosfield) sent this to me. I’m not sure who developed this procedure so I can’t give him/her the credit they deserve…it works quite well.

1) Accurately measure the distance from the rod tip to the front of the cork grip (not the entire rod length). Divide that number by 10. Example: 96″/10=9.6

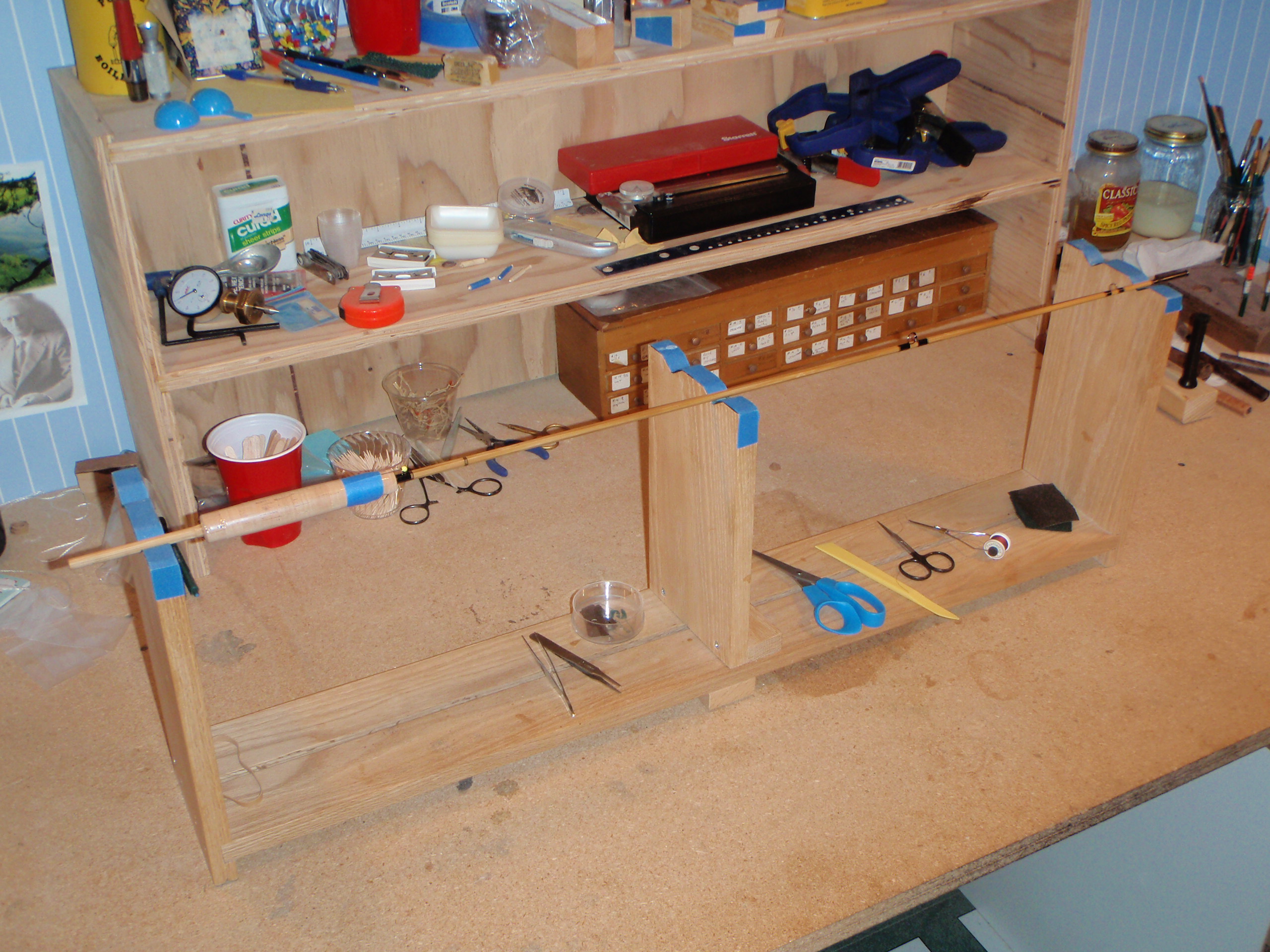

2) Clamp the rod grip to a table so that the rod is horizontal next to a wall. Mark the position of the tip of the rod on the wall. Put a paper clip through the top of a small plastic bag and hang the paper clip and bag to the tip of the rod. Slowly add small weights (coins, washers, nuts, etc.) to the bag until the tip flexes down exactly 1/10 of the measured rod length: Above example 9.6″.

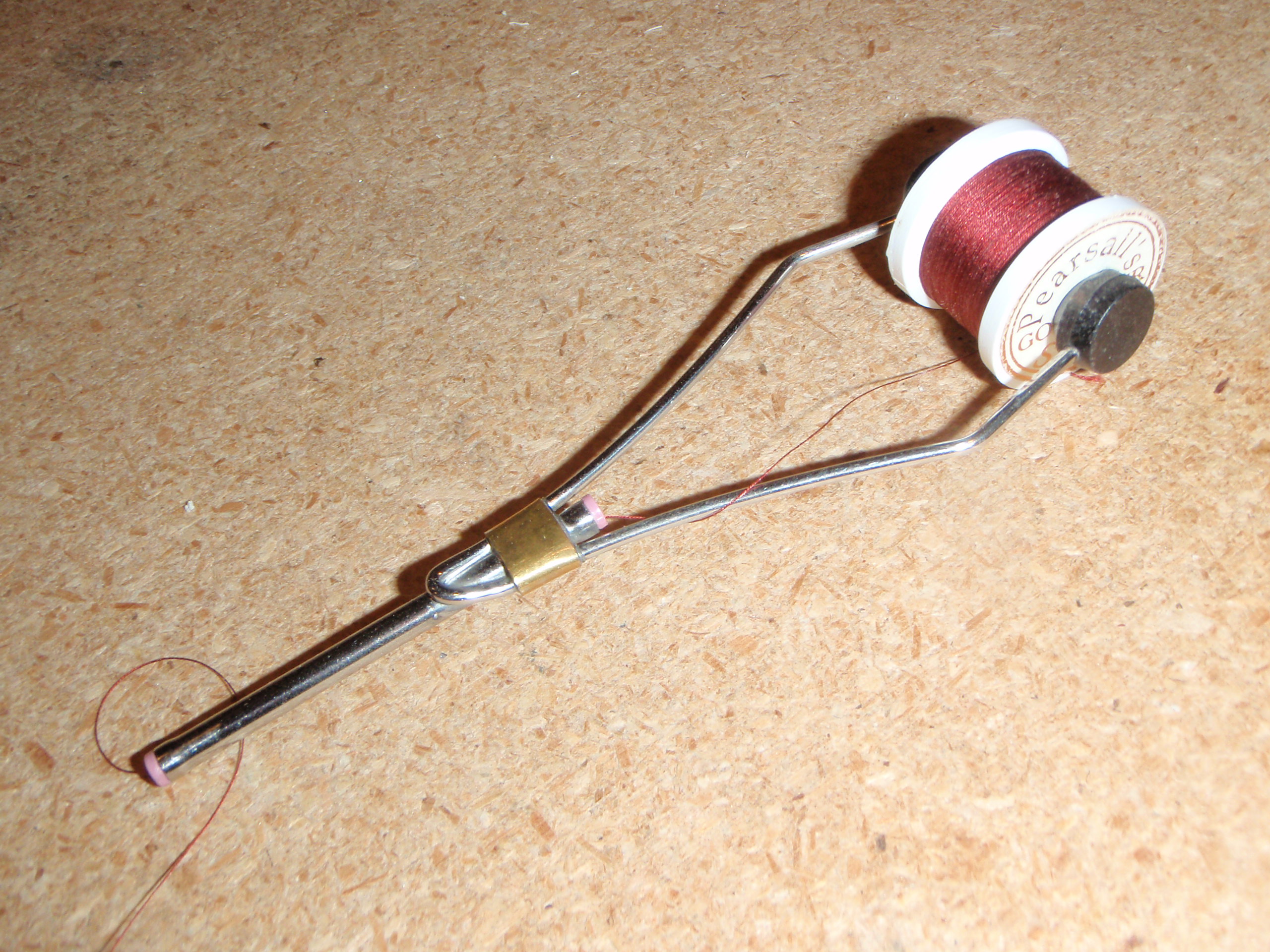

3) Remove the plastic bag, paper clip, and the weights you’ve added and weight everything on a gram scale. Example: Paper clip, bag, and coins collectively weighed 20 grams.

4) Divide the measured weight by adjusted rod length to get a grams/length ratio. Match the ratio to the recommended line weight in the table below: Example 20 grams/9.6″=2.1. This rod is about a 5 wt. rod.

Ratio Recommended Line Weight

1.4 – 1.6 3

1.6 – 1.9 4

1.9 – 2.2 5

2.2 – 2.6 6

2.6 – 3.0 7

3.0 – 3.5 8

3.5 – 4.2 9

4.2 – 5.0 10