Mary Ann has started building her second bamboo fly rod, so I now have two students in the shop working with me….keeps me pretty busy. She is building a very nice progressive 7′ 9″ 4 wt rod, perfect for dry flies on spring creeks. Here are a couple of photos from this past week.

Tag Archives: Bellingers

Bamboo Rod Building Class Update

I spent some time this week with Charlotte, my newest rod building class student. She’s making great progress, and keeps proclaiming “This is way too much fun!”. Here she is running bamboo strips through the Bellinger Hand Planers Friend. Next up for her…straightening strips and starting the hand planing process. Here is Charlotte in action:

New Bamboo Fly Rod is all Planed Up

I’ve been at the bench for a few days planing a new 8′ 0″ 3 piece, 4 wt rod. Lots of hours with a Stanley 9 1/2 in my hand, but finally finished. It always amazes me to see how small the tips get on these lighter rods. And, how much bamboo shavings get created from the planing operation. Next step, on to hollowing these sections prior to gluing.

Early Winter in Sisters, Oregon

We got hit pretty hard with an early winter storm for the past two days….temperatures in the teens and 18″ of snow at the house. So, we’re not planning on going anywhere for the next couple of days. I had to shovel my way out to my workshop this morning:

But, my shop is heated and it hasn’t slowed down my rod building. I put on a 4th coating of varnish on a 7′ 6″ 5 wt. rod I’m building for Rudy H. from Eugene, Oregon. Here is the rod hanging up in my drying cabinet. It will get one more coating of finish, followed by a hand polish, and then gluing on the reel seat.

Building a Hollow-Built Bamboo Switch Rod – Chapter 1

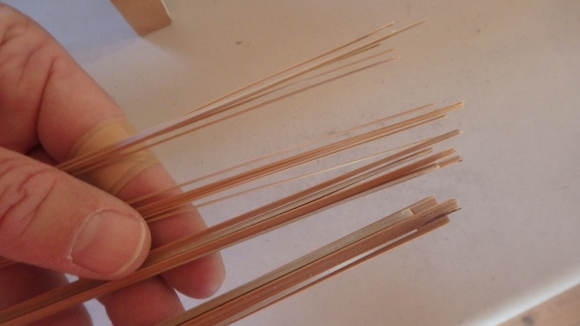

I recently started on another Hollow-Built Bamboo Switch Rod. I though it would be fun to document my process along the way, so here are some early photos. First, the bamboo is selected and split. For this Switch Rod, four pieces of matching bamboo were used.

After heat treating, the bamboo strips are roughed out into a triangular shape on a Bellinger Beveler.

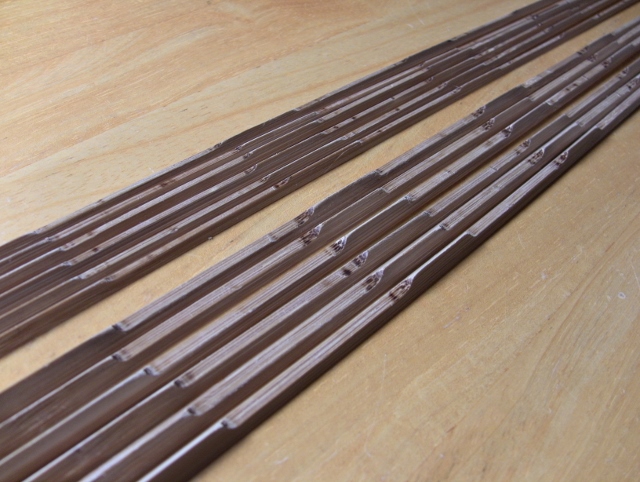

– The planed and hollowed bamboo strips are then glued together using Unibond 800 adhesive and a Bellinger Binder.

The thread holds the strips together under a constant tension until the glue cures.