Earlier this week we got the chance to hit Noname Creek (sorry, I’m sworn to secrecy) about 2 hours from Stanley in search for some hungry Cutthroats with our good friends, Noel and Sue, from Australia. Noel has one of my 8′ 3″ Signature Series 5 wt fly rods so that was his weapon of choice. Sue doesn’t fly fish but came along to enjoy the day on the stream and lend a hand with a net when needed. Mary Ann and I each took 7′ 0″ 4 wt rods. The trout were happy to take just about any dry fly we put their way and we were successful landing many nice fish. Here are a few photos from our day.

Tag Archives: gluing a bamboo rod

Building a Hollow-Built Bamboo Switch Rod – Chapter 1

I recently started on another Hollow-Built Bamboo Switch Rod. I though it would be fun to document my process along the way, so here are some early photos. First, the bamboo is selected and split. For this Switch Rod, four pieces of matching bamboo were used.

After heat treating, the bamboo strips are roughed out into a triangular shape on a Bellinger Beveler.

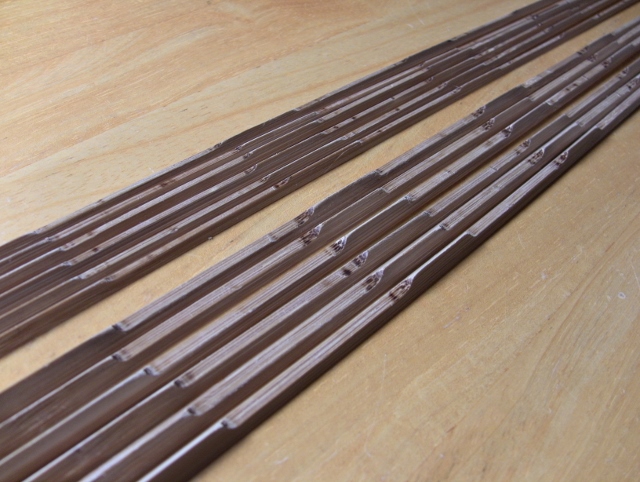

– The planed and hollowed bamboo strips are then glued together using Unibond 800 adhesive and a Bellinger Binder.

The thread holds the strips together under a constant tension until the glue cures.

Rod Building – Gluing Strips with the Bellinger Binder.

I’m working on a new rod right now and thought I would shoot a short video showing how the bamboo strips are glued together. I use a binder from Bellingers to accomplish this. Check it out! Oh, and by the way, how about my nice wallpaper in my rod finishing room. This room in my house was used as a boy’s bedroom by the previous homeowners. I have never felt the need to take it down.